Precast

detailing India is an experienced precast post tensioning services providers

firm with an expertise of a wealth of engineering and contracting experience

obtained through the successful completion of projects throughout USA, Canada,

Australia, UAE, UK and overseas over the last 7 years. Our

professional team of precast draftsman, precast detailers and precast engineers

uses latest technology to convert paper drawings, hand sketches and design

notes into a set of editable drawing formats. Precast detailing India participated in numerous domestic

and international precast concrete post tensioning services projects. These projects include

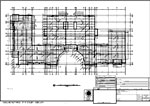

multi-story office buildings, schools and universities, stadiums, airports,

hospitals, and churches. We have been successful in establishing ourselves as a

quality supplier of precast post tensioning detailing drawings.

Post-tensioning

is a method of reinforcing (strengthening) concrete or other materials with

high-strength steel strands or bars, typically referred to as tendons.

Post-tensioning applications include office and apartment buildings, parking

structures, slabs-on-ground, bridges, sports stadiums, rock and soil anchors,

and water-tanks. In many cases, post tensioning allows construction that would

otherwise be impossible due to either site constraints.

Get a free

quotation: http://www.precastdetailingindia.com/inquiry.php

Our most

common post tension detailing drawings services includes:

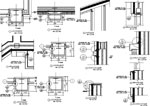

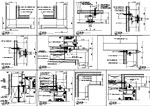

- Shop drawing Detailing of Post-Tension Building Structures

- Analysis and Design of Post-Tension Building Structures

- Field Placement Drawings

- Felt Calculations for Stress Losses

- Tendon and Chair Bills Of Material

- Bills Of Material in MS Excel Formats

- Drawings in AutoCAD and PDF Formats

- Multistrand Post-Tensioning Drawings

- Slab Post-Tensioning Detailing Drawings

- Multiwire Post-Tensioning Detailing Drawings

- Bar Post-Tensioning Detailing Drawings

- External Post-Tensioning Detailing Drawings

There are

two main types of post tensioning is unbonded and bonded (grouted).

An unbonded

tendon is one in which the prestressing steel is not actually bonded to the

concrete that surrounds it except at the anchorages. The most common unbounded

systems are monostrand (single strand) tendons, which are used in slabs and

beams for buildings, parking structures and slabs-on-ground. A monostrand

tendon consists of a seven-wire strand that is coated with corrosion-inhibiting

grease and encased in an extruded plastic protective sheathing. The anchorage

consists of an iron casting and a conical, two-piece wedge which grips the

strand.

In bonded

systems, two or more strands are inserted into a metal or plastic duct that is

embedded in the concrete. The strands are stressed with a large, multi-strand

jack and anchored in a common anchorage device. The duct is then filled with a

cementitious grout that provides corrosion protection to the strand and bonds

the tendon to the concrete surrounding the duct. Bonded systems are more

commonly used in bridges, both in the superstructure (the roadway) and in

cable-stayed bridges, the cable-stays. In buildings, they are typically only

used in heavily loaded beams such as transfer girders and landscaped plaza

decks where the large number of strands required makes them more economical. Contact

Us or Email: info@precastdetailingindia.com

to know more about our post tension detailing services and drawings.